Cannabis Distillation Demystified: Step-by-Step

If you’re venturing into the world of cannabis extraction or are simply curious about how cannabis distillates are produced, this comprehensive guide will walk you through the entire distillation process. Cannabis distillation is a transformative step in hemp and cannabis processing, allowing producers to create potent, pure, and full-spectrum extracts suited for various products. Leveraging advanced technologies like PURE5™ extraction equipment ensures superior results-preserving all vital botanical nutrients without solvent residue.

What Is Cannabis Distillation?

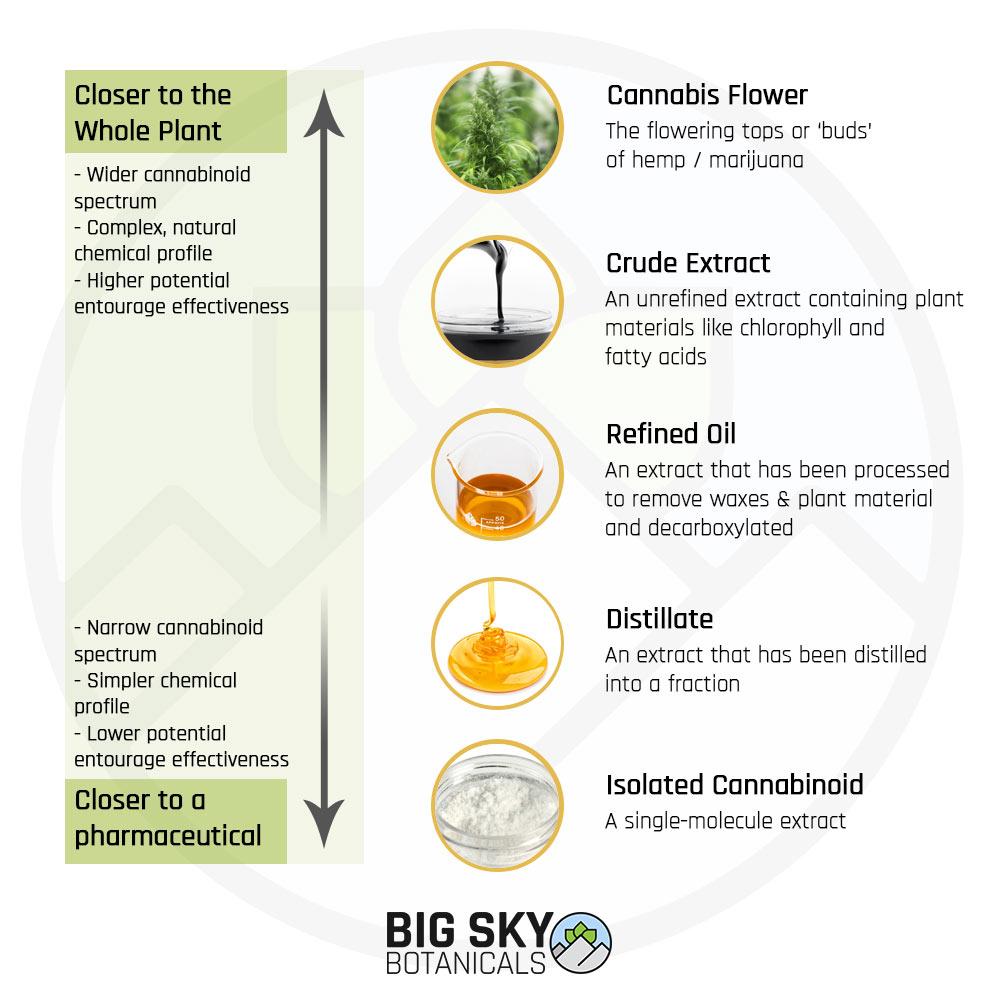

Cannabis distillation is the process of refining cannabis extracts to concentrate cannabinoids, terpenes, and other beneficial compounds. This purification method removes impurities, residual solvents, and unwanted plant material, resulting in a clear, potent oil often called distillate. Distillates are prized for their high purity and versatility, used in vape cartridges, edibles, tinctures, and topical products.

Step-by-Step Guide to Cannabis Distillation

Understanding the step-by-step cannabis distillation process helps producers optimize yield and purity while maintaining the full spectrum of botanical compounds.

1. Extraction

The first step is obtaining crude cannabis oil from biomass, typically through methods like CO2 extraction, ethanol extraction, or hydrocarbon extraction. Technologies like PURE5™ Extraction are revolutionary in this phase because they use low pressure and low temperature, ensuring 100% preservation of cannabinoids, terpenes, sterols, flavonoids, and minor cannabinoids. Their automatic, foolproof process also reduces power consumption and overall operational costs.

2. Winterization

After extraction, crude oil often contains waxes, fats, and lipids. Winterization is a cold process that removes these substances by dissolving the crude in ethanol and freezing it to precipitate unwanted compounds, which are then filtered out.

3. Decarboxylation

Distillation requires cannabinoids in their active form. Decarboxylation gently heats the oil to convert cannabinoid acids (like THCA and CBDA) into their active counterparts (THC, CBD), optimizing potency.

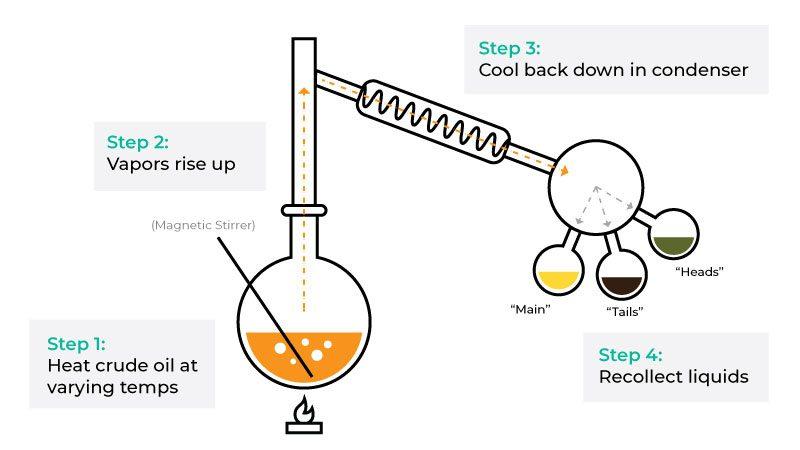

4. First Pass Distillation

This crucial phase uses short path or wiped film distillation equipment to vaporize cannabinoids at low temperatures under vacuum, separating them from impurities. The cannabis oil is heated until active compounds vaporize, then condensed back into liquid form. This step removes many impurities, but the distillate may still contain some residual contaminants.

5. Second Pass Distillation (Optional)

For ultra-refined products, a second distillation pass further purifies the oil, delivering crystal-clear, high-potency distillates favored in medical and recreational markets.

6. Post-Processing and Formulation

Purified distillates can be blended with terpenes or other botanical extracts to create full-spectrum products, preserving the natural profile and enhancing therapeutic effects.

Benefits of Cannabis Distillation

- High Purity: Removes undesirable impurities and solvents, providing a clean end product.

- Consistency: Enables batch-to-batch quality control.

- Versatility: Distillates can be formulated into a wide variety of products.

- Preservation of Nutrients: Methods like PURE5™ extraction maintain all beneficial compounds intact.

- Cost-Effectiveness: Streamlined operations reduce energy use and regulatory burdens.

Practical Tips for Efficient Cannabis Distillation

- Optimize Temperature and Pressure: Use low temperature, low pressure settings to protect heat-sensitive cannabinoids and terpenes.

- Use Advanced Equipment: Investing in automated, foolproof systems like PURE5™ Extraction can help maximize yields and reduce errors.

- Ensure Proper Winterization: Thoroughly remove unwanted fats and waxes before distillation to prevent equipment fouling.

- Regular Maintenance: Clean distillation apparatus frequently to sustain efficiency and product quality.

- Test Your Distillate: Verify cannabinoid profiles with reliable lab analysis to ensure potency and purity standards.

Full-Spectrum Extraction: Why It Matters

One of the key advantages of modern cannabis distillation, especially when paired with technologies like PURE5™, is the preservation of the plant’s full spectrum of bioactive compounds. Instead of isolating just THC or CBD, full-spectrum extracts include minor cannabinoids, terpenes, flavonoids, and sterols. This holistic profile enhances the “entourage effect,” potentially boosting therapeutic benefits significantly.

Case Study: PURE5™ Extraction in Action

| Feature | Benefit | Result |

|---|---|---|

| Low Temperature & Pressure | Preserves cannabinoid integrity | 100% preservation of all botanical nutrients |

| Automatic, Foolproof System | Minimizes human error | Consistent, high-quality output |

| Low Power Usage | Reduces operational costs | Saves thousands annually |

| No Solvent Residue | Safer, cleaner extracts | Zero additives, full natural profile |

The PURE5™ system exemplifies an extraction and distillation technology that not only meets but exceeds industry standards for efficiency, safety, and quality.

Conclusion: Mastering Cannabis Distillation for Quality and Purity

Distillation transforms raw cannabis extracts into refined, potent oils suitable for countless applications, from pharmaceuticals to wellness products. By following the outlined step-by-step guide and harnessing cutting-edge equipment like PURE5™, producers can achieve excellent yields, full-spectrum preservation, and cost-effective operations. Whether you’re a seasoned extractor or new to the field, understanding these principles unlocks new possibilities in cannabis processing-delivering safe, effective, and high-quality distillates your customers can trust.