cannabis extraction safety protocols”>

cannabis extraction safety protocols”>

Cannabis Extraction Safety Protocols: Best Practices

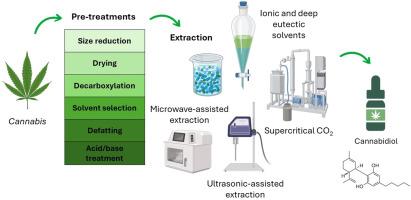

With the rapidly growing cannabis industry, efficient and safe extraction has become critical for producers aiming to deliver high-quality, full-spectrum extracts. Whether you’re extracting cannabinoids, terpenes, or other valuable compounds, it’s important to follow proven cannabis extraction safety protocols to protect your team, your product, and your facility.

In this comprehensive guide, we’ll walk through essential safety best practices, highlight innovative extraction technology – including the industry-leading PURE5™ system – and provide actionable tips that ensure your entire extraction process is safe, sustainable, and cost-effective.

Why Cannabis Extraction Safety Matters

Cannabis extraction involves the use of solvents, pressurized equipment, and specialized processes that pose potential risks such as fire, chemical exposure, and equipment malfunction. Without rigorous safety measures, operators risk injuries, product contamination, and costly downtime.

Beyond protecting personnel and facilities, safe extraction protocols directly influence product quality. Lowering exposure to heat, pressure, and contaminants preserves the plant’s delicate cannabinoids, terpenes, and flavonoids, ensuring full-spectrum extracts that consumers demand.

Key Cannabis Extraction Safety Protocols

1. Use Advanced, Automated Extraction Equipment

Choosing state-of-the-art extraction machinery addresses many hazards upfront. Systems like PURE5™ Extraction offer a streamlined, fully automatic, and foolproof process with:

- Low pressure and low temperature extraction for maximum nutrient preservation

- Recycled solvents and zero solvent residue to protect operator health

- Low regulatory requirements thanks to solvent-free and natural processing

2. Implement Proper Facility Design and Ventilation

A well-ventilated workspace with explosion-proof fixtures prevents the accumulation of flammable vapors. Ensure the extraction room is equipped with:

- Gas detection and alarm systems

- Emergency shutoff valves and ventilation overrides

- Non-sparking tools and electrical installations compliant with local codes

3. Enforce Comprehensive Personal Protective Equipment (PPE) Policies

Staff should always wear appropriate PPE including:

- Gloves resistant to chemicals and solvents

- Eye protection or face shields

- Flame-retardant lab coats or coveralls

4. Train Staff Thoroughly on Extraction Procedures and Emergency Response

Regular training reduces errors that could lead to accidents. Training topics should cover:

- Proper handling of raw materials and solvents

- Operation of extraction equipment and troubleshooting

- First aid, fire safety, and spill cleanup procedures

Benefits of Using PURE5™ Extraction Equipment for Safer Processes

PURE5™ extraction technology is revolutionizing cannabis and botanical extraction with its natural, solvent-free approach. Here’s why it stands out for safety and efficiency:

| Feature | Benefit |

|---|---|

| Low Pressure & Low Temperature | Minimizes risk of explosions and preserves sensitive compounds |

| Automatic, Foolproof Process | Reduces human error and enhances occupational safety |

| 100% Solvent Recycle & No Residue | Eliminates toxic solvent exposure and environmental contamination |

| Low Power Consumption | Decreases operating costs while supporting eco-friendly practices |

| Full-Spectrum, Natural Extracts | Retains cannabinoids, terpenes, sterols, and flavonoids without additives |

Practical Tips for Maintaining a Safe Cannabis Extraction Facility

- Routine Equipment Maintenance: Schedule regular inspections and servicing to identify wear or leaks early.

- Label All Chemicals Clearly: Avoid accidental misuse or mixing of incompatible substances.

- Keep Work Areas Clean: Remove plant debris and solvent residues to reduce fire hazards.

- Document Safety Protocols: Maintain accessible records of all procedures, inspections, and trainings.

- Monitor Environmental Conditions: Track temperature, humidity, and ventilation rates for optimal and safe operation.

- Emergency Planning: Establish clear evacuation routes and regularly test alarms and suppression systems.

Case Study: A Cannabis Farm’s Experience with PURE5™ Safety Improvements

A mid-sized cannabis grower recently integrated PURE5™ extraction into their post-processing workflow. Here’s what they experienced:

- Safety Incidents: Reported a 70% reduction in minor equipment-related injuries within six months.

- Energy Costs: Decreased overall power usage by 40%, saving thousands annually.

- Product Quality: Achieved consistently higher cannabinoid and terpene levels thanks to gentler extraction.

- Regulatory Compliance: Simplified permitting due to solvent-free operation.

Conclusion

Prioritizing safety in cannabis extraction isn’t just regulatory-it’s a business imperative that safeguards your team, elevates product quality, and optimizes your costs. By adopting best practices like comprehensive staff training, proper facility design, and most importantly, leveraging innovative extraction technology like PURE5™, you can create a safer and more effective extraction environment.

PURE5™ combines low temperature, low pressure, and zero solvent residue with a foolproof automated process, preserving all the rich, natural compounds your customers love, while minimizing risks and waste. Take the next step toward safer cannabis extraction today by integrating these protocols and technology in your operation.