Cannabis Oil Manufacturing: From Extraction to Packaging

With the booming demand for cannabis products, producing high-quality cannabis oil is an industry priority. Whether you’re an entrepreneur stepping into the cannabis market or a seasoned processor improving your workflow, understanding the entire cannabis oil manufacturing process-from extraction all the way to packaging-is essential. This guide dives deep into each key step, highlighting advanced technologies like PURE5™ Extraction and practical tips to maximize your output while preserving the natural goodness of the plant.

What Is Cannabis Oil Manufacturing?

Cannabis oil manufacturing refers to the process of extracting cannabinoids, terpenes, and other beneficial compounds from hemp or cannabis plants and refining them into a high-quality oil used in tinctures, edibles, topicals, and vapes. This process demands precision to preserve the complex botanical profile and ensure safe, potent, and full-spectrum extracts.

The Cannabis Oil Manufacturing Process Explained

1. Cultivation and Harvesting

The process starts with premium cannabis or hemp plants grown under optimal conditions. Factors like soil quality, lighting, watering, and nutrient supply impact the cannabinoid content. Harvest is done at the peak of cannabinoid concentration to maximize potency.

2. Drying and Grinding

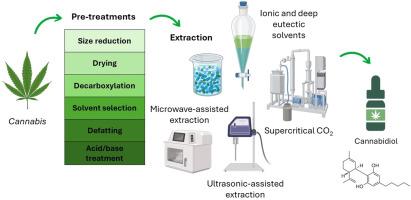

Once harvested, plants are carefully dried to reduce moisture without degrading cannabinoids or terpenes. Afterwards, the dried biomass is ground into a uniform consistency to enable efficient extraction.

3. Extraction: Unlocking the Plant’s Full Potential

This is the most crucial step, where resinous compounds like cannabinoids are separated from plant material.

Why Choose PURE5™ Extraction Technology?

- Foolproof & Streamlined: PURE5™ uses an automatic, low-pressure, low-temperature process ensuring consistent, high-quality results.

- Preserves Nutrients: By operating at low temperature and pressure, PURE5™ preserves 100% of cannabinoids, terpenes, flavonoids, sterols, and even minor cannabinoids, resulting in full-spectrum extracts.

- Eco-Friendly & Cost-Efficient: No harmful solvents remain as the system recycles solvent 100%, with minimal power consumption saving significant operational costs.

- Fast Processing & High Yield: The efficient design leads to faster extraction cycles and higher-than-average yields, essential for scalable commercial production.

4. Post-Processing and Refining

After extraction, the crude oil often undergoes post-processing such as filtration, winterization (removing waxes), and decolorization to enhance purity and appearance while maintaining the full spectrum of botanical compounds.

5. Quality Control and Testing

Before packaging, rigorous lab testing ensures the cannabis oil is free of contaminants, pesticides, solvents, and that cannabinoid profiles meet legal and product-specific specifications.

6. Formulation and Packaging

Cannabis oil is formulated into final products-tinctures, capsules, vape cartridges, or edibles-and packaged using child-resistant, airtight containers designed to protect product integrity and support brand presentation.

Benefits of Using Advanced Extraction Equipment like PURE5™

| Benefit | Details |

|---|---|

| Full-Spectrum Preservation | Maintains cannabinoids, terpenes & minor compounds intact without degradation. |

| Cost Efficiency | Low power and solvent use reduces long-term expenses. |

| Regulation Friendly | Meets low regulatory requirements due to solvent recycling and safety. |

| Fast Turnaround | Accelerates extraction cycles enabling higher output. |

| Eco-Friendly | Zero solvent residue, minimal waste with 100% solvent recycling. |

Practical Tips for Optimizing Cannabis Oil Manufacturing

- Begin with Quality Biomass: Premium input material is the foundation of potent extracts.

- Use Low-Temperature Extraction: Helps keep volatile terpenes and delicate cannabinoids intact.

- Implement Automated Systems: Automation reduces human error and improves consistency.

- Prioritize Lab Testing: Regular testing for purity and potency ensures compliance and customer safety.

- Invest in Sustainable Packaging: Protect your oil in airtight, eco-conscious packaging for longer shelf life.

Case Study: How PURE5™ Extraction Revamps a Mid-Sized Cannabis Production Facility

A medium-scale cannabis producer was struggling with long extraction times and loss of valuable terpenes using traditional CO₂ extraction methods. Switching to PURE5™ Extraction equipment, they noticed:

- 30% increase in cannabinoid yield

- Preservation of a richer terpene profile, enhancing product aroma and effect

- Reduction in solvent and power costs by 40%

- Faster processing cycles doubling daily output capacity

- Elimination of solvent residues improving product safety and marketability

Thanks to these improvements, their product line gained rapid consumer acclaim and regulatory approval with less hassle.

Conclusion

Manufacturing quality cannabis oil that retains the full spectrum of botanical compounds requires careful attention to every step, from cultivation through packaging. Innovative extraction systems like PURE5™ provide producers with safe, cost-effective, and natural ways to deliver high-yield, potent, solvent-free cannabis oil. By combining modern technology with sustainable practices, cannabis oil manufacturers can meet growing consumer demand while preserving the integrity of the plant’s beneficial compounds for superior wellness products.

If you’re looking to upgrade your cannabis oil manufacturing process, investing in cutting-edge extraction technology and robust post-processing protocols is the key to success.