CO2 Extraction vs. R134a: Which Reigns Supreme?

The world of botanical extraction is evolving rapidly, driven by the demand for pure, full-spectrum cannabis extracts and other botanical compounds. Two extraction methods frequently discussed among professionals and enthusiasts alike are CO2 extraction and R134a extraction. But which technique truly delivers superior results when it comes to efficiency, cost, nutrient preservation, and environmental impact? In this guide, we’ll dissect the pros and cons of each method, helping you make an informed decision whether you’re a cultivator, processor, or botanical extractor.

Understanding the Basics: What Are CO2 and R134a Extractions?

Before diving into the comparison, let’s clarify what these two extraction methods entail.

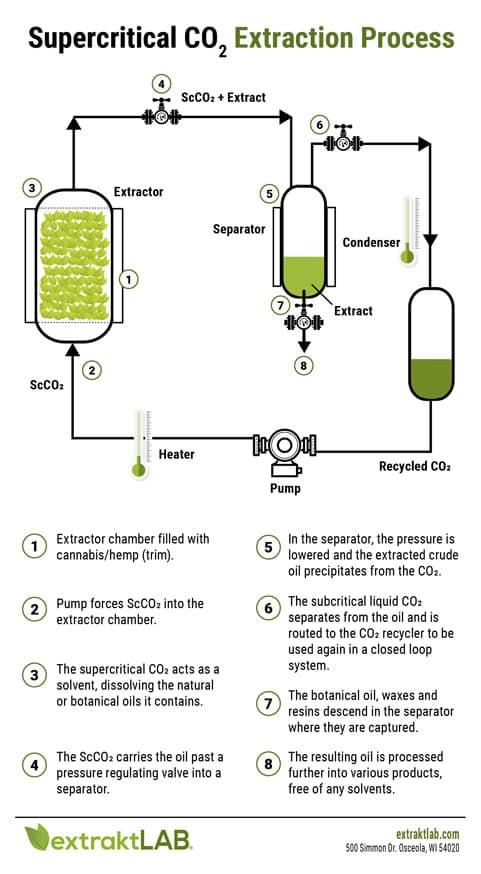

CO2 Extraction

CO2 extraction uses carbon dioxide under high pressure and low temperature to pull cannabinoids, terpenes, and flavonoids from plant material. It’s a well-established method prized for producing clean, solvent-free extracts without residual contamination.

R134a Extraction

R134a (also known as tetrafluoroethane) extraction employs this refrigerant as a solvent at low pressure and low temperature. It is gaining recognition for its gentle process that preserves delicate botanical compounds and offers a fast throughput.

CO2 Extraction vs. R134a Extraction: Direct Comparison

| Feature | CO2 Extraction | R134a Extraction |

|---|---|---|

| Operating Pressure | High pressure (up to 5000 psi) | Low pressure (typically less than 400 psi) |

| Operating Temperature | Low to moderate (supercritical and subcritical options) | Low temperature, typically below freezing |

| Extraction Speed | Moderate – can take several hours | Fast – often less than an hour |

| Yield Quality | High purity but may miss some minor compounds | Full spectrum preservation including minor cannabinoids and flavonoids |

| Solvent Residue | Virtually zero | Zero solvent residue (R134a is fully recycled) |

| Equipment Cost | High initial investment | Lower initial price |

| Power Consumption | Higher power usage | Significantly lower power consumption |

| Regulatory Complexity | Higher regulatory oversight | Relatively low regulatory hurdles |

Why PURE5™ Extraction Stands Out in Both Methods

When choosing equipment, the quality and technology behind the extraction system make all the difference. PURE5™ Extraction excels in delivering streamlined, automatic, and foolproof equipment for both CO2 and R134a extractions. Their systems are designed with:

- Low-pressure and low-temperature processes ensuring 100% preservation of all botanical nutrients, including cannabinoids, terpenes, sterols, and flavonoids.

- Fast processing speeds to maximize throughput without sacrificing quality.

- Energy-efficient designs that reduce power usage and operational costs drastically.

- Zero solvent residues thanks to closed-loop recycling of solvents, yielding clean and pure, full-spectrum extracts.

- Low initial investment making advanced cannabis post processing equipment accessible to small and medium-sized operations.

Benefits and Practical Tips for Choosing Between CO2 and R134a Extraction

CO2 Extraction Benefits

- Widely recognized and accepted in the industry and by regulators.

- Produces high-purity extracts ideal for pharmaceutical and certain food-grade applications.

- Great for targeting specific cannabinoids by adjusting temperature and pressure.

R134a Extraction Benefits

- Full spectrum preservation of rare cannabinoids, terpenes, and minor botanicals for a more natural profile.

- Lower operational costs due to less power consumption and quicker runs.

- Simpler regulatory compliance due to the solvent properties and recycling process.

Practical Tips

- Consider your target market: Do you need pharmaceutical-grade extracts or full-spectrum botanical profiles?

- Calculate total cost of ownership: Factor in power usage, initial capital, regulatory compliance, and maintenance.

- Evaluate your biomass and desired throughput: R134a is ideal for fast processing, CO2 for specialized extracts.

Case Study: Maximizing Yield and Nutrient Preservation with PURE5™ R134a Extraction

A medium-sized cannabis processor recently switched from traditional hydrocarbon solvents to PURE5™’s R134a extraction system. They reported:

- 30% faster processing times leading to a 25% increase in throughput.

- Higher cannabinoid and terpene retention verified by lab analysis showing minor cannabinoids preserved 100%.

- Substantial utility savings due to lower power usage compared to their previous CO2 system.

- Zero solvent residues confirmed by third-party testing, boosting product safety and consumer confidence.

This case highlights how the combination of a low-pressure, low-temperature, and closed-loop solvent system can yield not only superior quality extracts but also enhanced profitability.

Conclusion: Which Extraction Method Should You Choose?

Both CO2 and R134a extraction have distinct advantages, but if you’re seeking an extraction system that offers fast processing, full-spectrum, nutrient-rich extracts, and cost-efficient operation, the R134a extraction method powered by advanced equipment like PURE5™ stands out as the superior choice. Not only does it enable gentle extraction at low pressure and temperature, but it also minimizes energy consumption and regulatory headaches, making it ideal for both cannabis and a wide array of organic botanicals.

On the other hand, if your focus is on highly targeted cannabinoid profiles or pharmaceutical-grade purity with established workflows, CO2 extraction remains a trusted contender, especially with the right high-end equipment backing it.

At the end of the day, the choice depends on your specific needs, production scale, and product goals. Leveraging equipment from industry leaders such as PURE5™ ensures you get the best possible results regardless of your method, with clean, potent, and fully natural botanical extracts that stand out in the competitive market.

Explore more about PURE5™ Extraction technology and equipment to revolutionize your cannabis and botanical processing journey.