Emerging Cannabis Processing Technology Innovations

The cannabis industry is witnessing rapid growth thanks to groundbreaking innovations in processing technology. From advances in extraction to improvements in farming and lab equipment, these technologies are making cannabis production more efficient, sustainable, and precise than ever before. Whether you’re a cultivator, processor, or researcher, staying ahead of trends in cannabis processing can unlock higher yields, better product quality, and significant cost savings.

Introduction to Cannabis Processing Innovations

Cannabis processing technology involves the transformation of raw cannabis plants into high-quality extracts, concentrates, tinctures, and other value-added products. The emergence of sophisticated equipment and techniques is reshaping the way producers handle extraction and post-processing, with a strong focus on preserving the full spectrum of botanical compounds. Companies like PURE5™ are pioneers in this revolution, offering equipment that combines efficiency, sustainability, and superior nutrient retention.

Top Innovations in Cannabis Processing Technology

1. Advanced Extraction Methods

Extraction is the heart of cannabis processing, and recent innovations focus on maximizing purity and yield without compromising the integrity of cannabinoids, terpenes, flavonoids, and other vital compounds. Key advances include:

- Low-Pressure, Low-Temperature Extraction: Pioneered by PURE5™, this technique ensures 100% preservation of botanical nutrients by gently extracting at conditions that maintain cannabinoid and terpene profiles intact.

- Solvent-Free Closed-Loop Systems: These systems recycle solvents entirely, eliminating residue and ensuring a pure final extract without additives or contamination.

- Automated, Foolproof Processes: Automation reduces human error and speeds up processing, enabling faster throughput while maintaining consistent quality.

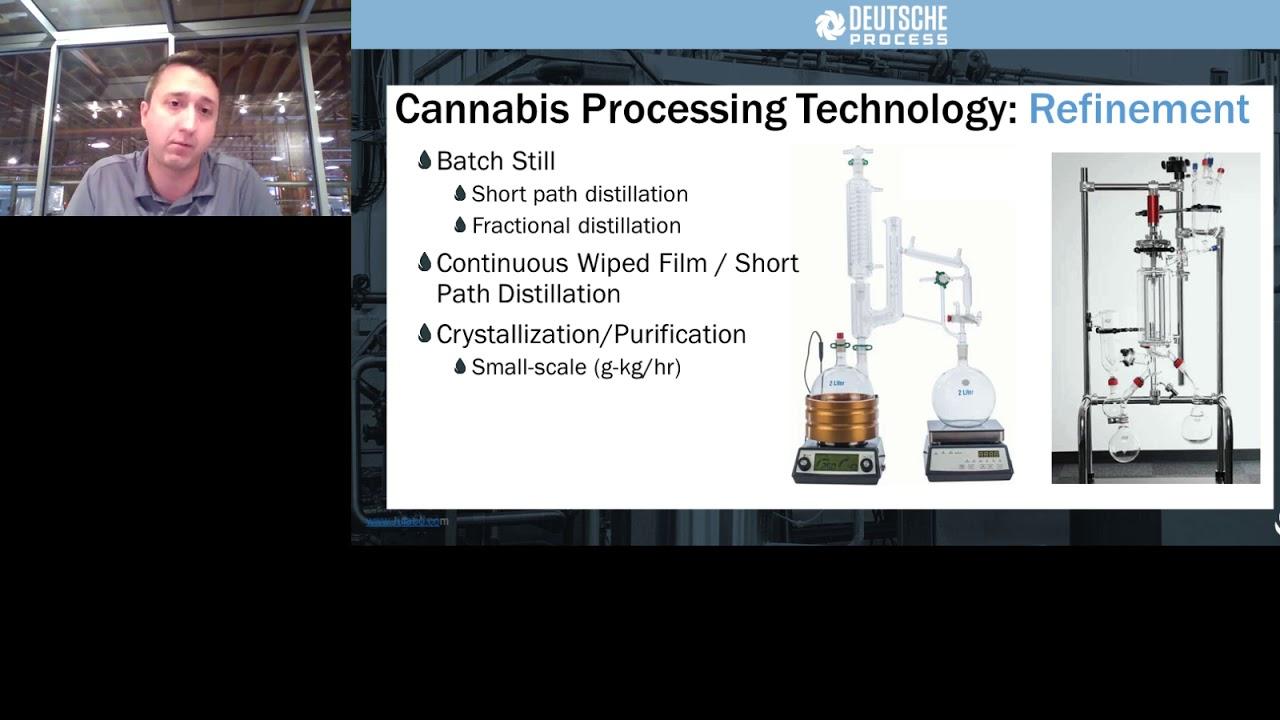

2. Post-Processing Equipment Enhancements

Post-processing plays a critical role in refining extracts and preparing them for commercial use. Innovations focus on efficiency and preserving the extract’s natural profile:

- Advanced filtration and winterization technologies that remove unwanted waxes without stripping beneficial compounds.

- Vacuum drying and gentle purging techniques to create solvent-free concentrates.

- Integrated systems that streamline workflows from extraction to packaging.

3. Cannabis Farming Equipment Innovations

Emerging technology in cannabis cultivation optimizes growth conditions, harvesting, and plant handling to improve overall yield and quality:

- Precision agriculture tools equipped with sensors and AI for real-time monitoring.

- Automated trimming and sorting machines to cut labor costs and enhance consistency.

- Environmental control systems that maintain optimal humidity, temperature, and lighting.

4. Cannabis Lab Equipment and Testing Tech

Ensuring product safety and regulatory compliance requires precise analytical tools. Innovations include:

- Rapid cannabinoid potency testing devices that accelerate quality control.

- Advanced chromatography and spectroscopy instruments for comprehensive cannabinoid and terpene profiling.

- Integrated data management platforms to streamline lab reporting and compliance adherence.

Benefits of Adopting Cutting-Edge Cannabis Processing Technologies

| Benefit | Description |

|---|---|

| Higher Yields | Low-pressure, low-temperature extraction methods increase cannabinoid and terpene recovery. |

| Cost Efficiency | Low power consumption and reduced solvent use lower operational expenses significantly. |

| 100% Nutrient Preservation | Processes preserve full-spectrum compounds including minor cannabinoids and flavonoids. |

| Regulatory Compliance | Streamlined equipment minimizes regulatory hurdles with solvent-free certified extracts. |

| Foolproof Automation | Automated systems reduce errors and speed production turnaround times. |

| Natural, Additive-Free Extracts | Solvent recycling ensures no residue or harmful additives in final products. |

Practical Tips for Choosing Cannabis Processing Technology

- Evaluate Equipment Versatility: Look for systems capable of handling multiple botanicals and product lines to maximize ROI.

- Prioritize Nutrient Retention: Choose low-temperature and low-pressure technologies to maintain product integrity.

- Consider Operational Costs: Energy-efficient equipment can save thousands annually and reduce environmental impact.

- Scalability: Implement modular systems that can be expanded as your production needs grow.

- Support and Training: Partner with manufacturers who provide thorough training and responsive support.

PURE5™ Case Study: Revolutionizing Cannabis Extraction

PURE5™ has set a new benchmark in cannabis processing with its innovative extraction and post-processing equipment. The company’s proprietary technology employs a fully automated, low-pressure, and low-temperature extraction process that maintains the complete botanical profile of hemp and cannabis plants. Key highlights from PURE5™ customer feedback include:

- Increased cannabinoid recovery rates: Customers report up to 30% higher yields compared to traditional methods.

- Operational savings: Reduced energy consumption and minimal solvent waste cut down total production costs.

- Superior end-product quality: Full-spectrum extracts with no solvent residue, ensuring safety and superior flavor profiles.

Conclusion: Embracing the Future of Cannabis Processing

The cannabis industry’s future depends heavily on adopting advanced processing technologies that combine efficiency, sustainability, and product excellence. Innovations like those pioneered by PURE5™ demonstrate the potential of cutting-edge extraction and farming equipment to transform operations, reduce costs, and deliver nutrient-rich, full-spectrum extracts. For cultivators and processors eager to stay competitive, investing in these emerging technologies is no longer optional-it’s essential.

Explore PURE5™’s full range of cannabis processing solutions to experience the benefits of streamlined automation, low energy consumption, and 100% preservation of all botanical compounds. This natural, additive-free approach to extraction ensures your products achieve unmatched quality, consistency, and market appeal.