Ethanol Extraction: Pros, Cons, and Techniques

As the demand for pure, high-quality cannabis and botanical extracts surges, ethanol extraction has emerged as a popular method among processors and growers alike. From capturing the full spectrum of cannabinoids to allowing scalable production, ethanol extraction blends efficiency and quality in a way that fits many business needs.

In this article, we’ll dive deep into what ethanol extraction is, its pros and cons, and the latest techniques that define the industry. Plus, you’ll learn practical tips to maximize results and how leading experts like PURE5™ Extraction revolutionize the process through innovative equipment and natural, full-spectrum extracts.

What Is Ethanol Extraction?

Ethanol extraction involves using ethanol (ethyl alcohol) as a solvent to pull cannabinoids, terpenes, flavonoids, and other valuable compounds from cannabis or botanical materials. It is a versatile and widely used extraction method due to ethanol’s effectiveness at dissolving both polar compounds and oils, making it ideal for full spectrum extracts.

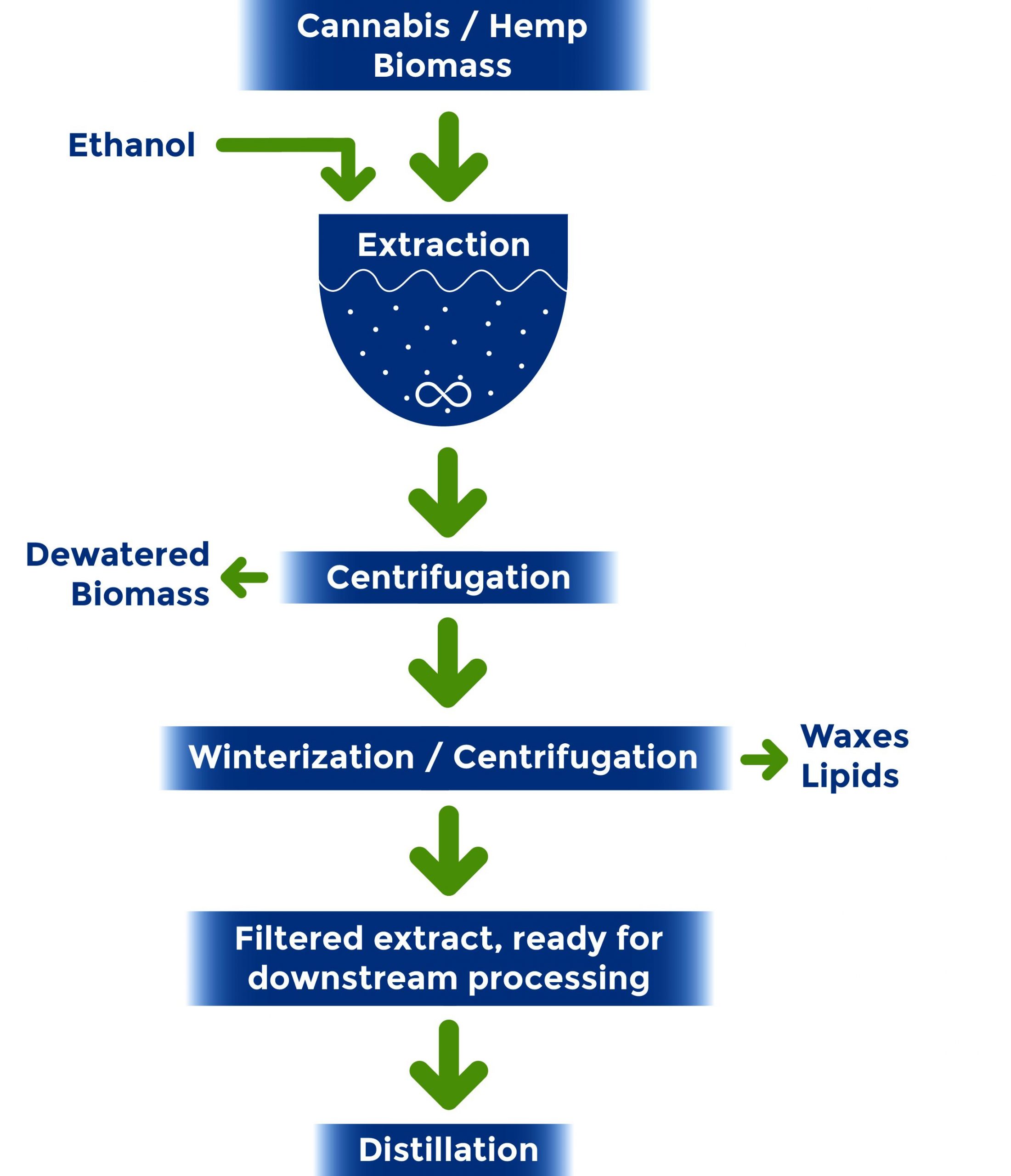

How Does Ethanol Extraction Work?

The process usually starts by soaking or rinsing the plant material in ethanol, which acts as a solvent to dissolve desired compounds. After sufficient contact, the solution is filtered to separate plant solids. Then, ethanol is evaporated through heat and vacuum techniques, leaving behind a concentrated oil rich in cannabinoids and terpenes.

“Ethanol extraction’s ability to preserve essential plant molecules by using low temperatures and gentle processes makes it a leader in botanical extraction technology.”

Pros of Ethanol Extraction

- Full Spectrum Extraction: Ethanol captures a broad range of compounds including cannabinoids, terpenes, flavonoids, and sterols, offering a rich, natural profile.

- Food-Grade and Safe: Being food-grade safe (GRAS status), ethanol is preferred for products that require purity and no toxic residues.

- Fast and Scalable: Ethanol extraction suits both small craft growers and large-scale facilities due to its speed and adaptability.

- Low Temperature & Pressure: These conditions help to protect sensitive compounds, preserving plant nutrients and flavors better than harsher methods.

- Eco-Friendly & Cost-Effective: Ethanol can be recycled within the process, reducing waste and usage costs, while keeping energy consumption low.

- Low Regulatory Burden: Compared to hydrocarbon solvents, ethanol faces fewer regulatory hurdles in many jurisdictions.

Cons of Ethanol Extraction

- Co-extraction of Chlorophyll: Ethanol can extract unwanted chlorophyll and waxes that can impact flavor and color if not removed properly.

- Post-Processing Steps Required: Additional refining like winterization and filtration is often necessary to produce a smooth, high-quality oil.

- Flammability Concerns: Ethanol is highly flammable, necessitating strict safety protocols and equipment.

- Initial Equipment Investment: While the process itself is affordable, high-quality extraction and recovery systems have upfront costs.

Common Ethanol Extraction Techniques

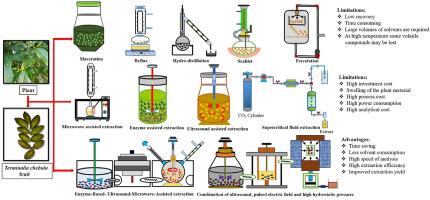

1. Cold Ethanol Extraction

In cold ethanol extraction, ethanol is chilled to subzero temperatures (-20°C to -40°C) before introduction to plant material. Chilling minimizes unwanted waxes and chlorophyll extraction, resulting in cleaner crude oil. This method preserves delicate compounds effectively and enhances yield quality.

2. Room Temperature Extraction

This simpler method uses ethanol at ambient temperatures. It’s faster and less expensive but often requires more intensive downstream refining to remove impurities.

3. Soxhlet Extraction

A traditional lab-scale method where ethanol repeatedly washes the plant material through continuous reflux. It’s precise but less suitable for larger industrial operations.

4. Continuous Flow Extraction

Optimized for large volume production, continuous flow systems pass ethanol through biomass continuously, improving throughput and consistency.

| Technique | Temperature | Purity Level | Ideal For |

|---|---|---|---|

| Cold Ethanol | -20°C to -40°C | High | High purity craft/extracts |

| Room Temperature | 20°C to 25°C | Moderate | Cost-conscious operations |

| Soxhlet | Controlled Lab Temp | Lab-scale Purity | Research & small scale |

| Continuous Flow | Variable | Consistent | Large scale industrial |

Maximizing Ethanol Extraction Efficiency: Practical Tips

- Use Chilled Ethanol: Lower temperatures reduce chlorophyll and wax extraction for cleaner crude.

- Pre-Freeze Biomass: Freezing plant material before extraction preserves delicate terpenes and cannabinoids better.

- Optimize Soak Time: Balance extraction speed with thoroughness; excessive soak times may pull unwanted compounds.

- Invest in Modern Equipment: Using advanced, streamlined systems like those developed by PURE5™ Extraction ensures faster processing, lower power consumption, and higher yields.

- Recycle Ethanol: Recovery units that purify and reuse ethanol drive down costs and enhance sustainability.

PURE5™ Extraction: Elevating Ethanol Extraction to a New Level

When it comes to ethanol extraction equipment and full botanical post-processing, PURE5™ stands out as an industry leader. Their streamlined, automatic, and foolproof systems offer low-power usage and low-pressure, low-temperature operation. This technology guarantees 100% preservation of cannabinoids, terpenes, flavonoids, sterols, and even minor cannabinoids, delivering an unmatched natural full-spectrum extract with no additives or solvent residue.

Furthermore, PURE5™’s equipment requires minimal regulatory overhead, which helps operators save on compliance costs and simplifies the entire extraction process. Fast processing, low initial investment, and higher yields make PURE5™ ideal for growers and extractors looking to scale responsibly without sacrificing quality.

Conclusion

Ethanol extraction remains a top choice for cannabis and botanical oil extraction due to its versatility, safety, and ability to produce full-spectrum extracts rich in beneficial compounds. While challenges like chlorophyll co-extraction and equipment costs exist, the benefits often outweigh the drawbacks when done properly.

Adopting advanced techniques-particularly cold ethanol extraction-and investing in cutting-edge equipment such as that offered by PURE5™ Extraction can transform your extraction operation, enhancing efficiency, yield, and product quality.

Whether you’re a craft extractor or an industrial grower, understanding the pros, cons, and nuances of ethanol extraction empowers you to produce superior botanical extracts that stand out in a competitive market.

Ready to elevate your extraction process? Discover how PURE5™ technology can help you unlock the true potential of your cannabis and botanicals today.