How to Choose the Best Cannabis Extraction Equipment

Whether you’re a cannabis farmer, a lab technician, or a botanical product developer, selecting the right cannabis extraction equipment is crucial for achieving high-quality, full-spectrum extracts that preserve the delicate nutrients and compounds of the plant. With so many options on the market, it can be overwhelming to know which equipment suits your scale, budget, and product goals.

In this guide, we’ll cover everything you need to consider when choosing extraction gear – from technology types and processing speed to regulatory compliance and the preservation of cannabinoids and terpenes. Plus, you’ll discover why PURE5™ Extraction stands out as a top choice for industry professionals looking for a streamlined, natural, and efficient extraction method.

Why Choosing the Right Extraction Equipment Matters

Extraction is more than just separating cannabinoids like THC or CBD from the plant material. The process impacts the quality, yield, purity, and nutritional value of your final product. Using inferior or incompatible equipment may result in:

- Loss of precious compounds such as terpenes, flavonoids, and minor cannabinoids

- Low extraction yield leading to increased costs

- Residues of solvents or additives that degrade purity

- Increased power consumption and operational expenses

- Difficulty complying with strict regulatory requirements

Investing in the best extraction systems means better product integrity, higher profits, and a cleaner, safer product for consumers.

Factors to Consider When Choosing Cannabis Extraction Equipment

1. Extraction Technology

Common cannabis extraction methods include CO2 supercritical, ethanol, hydrocarbon, and mechanical extraction. Each comes with pros and cons:

| Extraction Type | Advantages | Considerations |

|---|---|---|

| CO2 Supercritical | Clean, solvent-free, precise extraction; preserves flavor | Expensive equipment; requires operator training |

| Ethanol | Fast, effective for large batches; safe when properly evaporated | May require solvent removal; potential residual solvents if not careful |

| Hydrocarbon (Butane, Propane) | High yield and potency; preserves terpenes well | Explosive risk; more regulatory hurdles |

| Mechanical (Rosin Press) | Solventless, simple operation; natural extraction | Lower yields; limited for large-scale use |

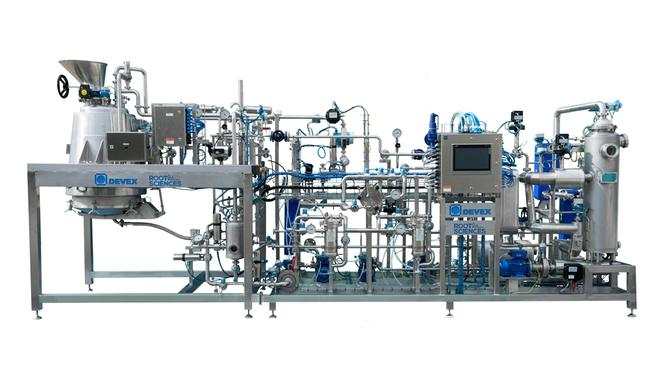

PURE5™ Extraction takes a unique approach by using a patented low-pressure, low-temperature process that preserves 100% of cannabinoids, terpenes, flavonoids, and other botanicals naturally – without additives or solvent residues. This ensures you retain the full botanical spectrum and nutritional profile in every batch.

2. Capacity and Throughput

How much raw material do you plan to process daily? Equipment comes in various sizes for everything from small craft batches to industrial-scale operations.

- Startups or small labs: Look for smaller machines with quick turnaround but good yields.

- Medium-sized farms: Medium-capacity equipment balancing speed and quality.

- Large commercial operations: High-throughput systems with automated processing for cost-efficiency.

PURE5™ Extraction systems are streamlined and fully automatic, enabling fast processing with low power usage, which dramatically saves on operational costs, making it ideal for any scale.

3. Purity and Preservation of Compounds

The goal is always to preserve the natural profile of the cannabis plant. Look for equipment with:

- Low-temperature extraction to avoid heat degradation

- Low-pressure operation to protect delicate compounds

- No harmful solvents or additives added

- Zero solvent residues with recycling capability

PURE5™ excels here – their technology ensures 100% preservation of important compounds like cannabinoids, terpenes, sterols, and flavonoids, offering an unmatched real full-spectrum extract.

4. Regulatory Compliance and Safety

Choose equipment designed to meet or exceed your local and industry regulations. Automated systems with foolproof processes reduce the risk of human error and contamination. Additionally, low regulatory requirements mean easier permits and inspections.

5. Energy Efficiency and Operational Costs

Extraction machines can consume significant energy; therefore, low power usage is a vital factor for long-term savings. Newer technologies such as PURE5™’s require far less electricity compared to traditional methods, helping you reduce your carbon footprint and overhead.

Benefits of Using PURE5™ Extraction Equipment

- Streamlined, fully automatic operation: Minimizes labor and error.

- Low initial investment: High value for money, suitable for startups and large businesses alike.

- Fast processing speed: Increases throughput without compromising quality.

- Higher yields: Extract more from your raw material effectively.

- Natural full-spectrum extracts: Retains cannabinoids, terpenes, flavonoids, and even minor cannabinoids intact.

- No additives or solvent residues: Ensures clean and safe products.

- Low temperature and pressure extraction: Protects sensitive botanical nutrients.

- Energy savings: Low power usage reduces operational costs significantly.

Practical Tips for Getting Started with Cannabis Extraction

- Define your end product goals: Are you focusing on oils, distillates, isolates, or full-spectrum extracts? This informs your equipment choice.

- Assess your budget and capacity needs: Balance initial costs with operational expenses and scale requirements.

- Request demonstrations and testimonials: Real-world feedback helps validate claims.

- Prioritize equipment with low regulatory hurdles: Save time and hassle down the road.

- Choose technology that maintains natural integrity: Aim for 100% preservation of botanical compounds for premium products.

Case Study: How a Mid-sized Hemp Farm Maximized Yield with PURE5™

Green Leaf Hemp Farm, processing 500 kilograms of biomass weekly, switched from traditional ethanol extraction to PURE5™ Extraction equipment in early 2023. Within three months, they reported:

- 20% increase in overall cannabinoid yields

- Significant reduction in operational energy costs by 35%

- Improved compliance with state regulations due to clean, solvent-free extracts

- Enhanced product flavor and quality, maintaining full-spectrum profiles sought by customers

This switch translated to higher profits and a strong competitive edge in the marketplace.

Conclusion

Choosing the best cannabis extraction equipment is a strategic decision that can determine the success of your cannabis or botanical business. Prioritize technologies that offer high yields, natural full-spectrum preservation, low operational costs, and regulatory friendliness. PURE5™ Extraction represents one of the industry’s leading solutions, with a foolproof, streamlined process delivering premium, natural extracts efficiently and affordably.

Ready to elevate your extraction process? Explore PURE5™’s innovative equipment and experience how cutting-edge technology can transform your cannabis or botanical extraction journey.

Learn more about PURE5™ Extraction equipment here.