Industrial Cannabis Extraction: Scaling Up Safely

As the cannabis industry continues to flourish, the demand for high-quality, full-spectrum extracts is skyrocketing. Scaling up industrial cannabis extraction comes with its own set of challenges – from maintaining product integrity and regulatory compliance to optimizing cost-efficiency and safety protocols. Whether you’re a seasoned operator or just venturing into large-scale cannabis processing, understanding how to scale up safely is critical for success.

Why Safe Scaling Matters in Cannabis Extraction

Scaling extraction processes poses risks that can’t be overlooked. Without proper equipment and protocols, you risk product degradation, safety hazards, and higher operational costs. These factors can hurt profitability and brand reputation.

- Preserving Botanical Integrity: High temperatures and pressures can degrade sensitive cannabinoids, terpenes, and flavonoids.

- Regulatory Compliance: Industrial setups must comply with strict regulations to avoid shutdowns and legal complications.

- Operational Safety: Working with solvents and botanicals requires foolproof systems to protect workers and facilities.

- Cost Efficiency: Scaling must maintain or improve yields without drastically increasing energy consumption or waste.

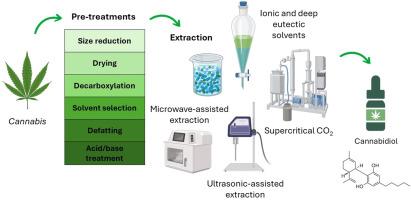

Choosing the Right Extraction Technology

One of the most important decisions when scaling up is selecting an extraction system that balances efficiency with safety and product quality. Among the top choices in the industry is the PURE5™ Extraction system, renowned for its streamlined, automatic, and foolproof process design.

Key Advantages of PURE5™ Extraction

- Low-Pressure and Low-Temperature Extraction: Ensures 100% preservation of all botanical nutrients, including cannabinoids, terpenes, sterols, and flavonoids.

- Natural Full-Spectrum Extracts: Retains the full botanical profile without additives or solvent residues, thanks to its closed-loop solvent recycling.

- Energy Efficiency: Consumes significantly less power compared to traditional extraction methods, saving money and reducing environmental footprint.

- Low Initial Investment: Offers a cost-effective entry into industrial-scale extraction, ideal for growing operations.

- Fast Processing Times: Accelerates throughput, boosting productivity without compromising quality.

- Minimal Regulatory Burden: Designed to meet regulatory requirements with ease, facilitating smoother operational licensing.

Practical Tips for Scaling Up Industrial Cannabis Extraction

1. Plan for Product Consistency

Consistency is king in the cannabis market. Maintain tight control over extraction conditions, harvest input quality, and post-processing steps to ensure your products meet customer expectations batch after batch.

2. Implement Robust Safety Protocols

Establish clear safety SOPs, train staff rigorously, and invest in equipment with built-in safety features. PURE5™’s foolproof automatic process significantly reduces human error risks.

3. Optimize Workflow Efficiency

Integrate post-processing and farming equipment that complements your extraction system for seamless operations and increased yields. PURE5™’s solutions support full operational workflows from farming to lab testing.

4. Monitor Regulatory Developments

Stay ahead of regulatory changes to ensure compliance and avoid costly disruptions. Systems like PURE5™ help reduce complexity, making adherence straightforward.

Case Study: Scaling with PURE5™ Extraction

GreenLeaf Botanicals, a mid-sized hemp processor, wanted to increase their extraction capacity by threefold while preserving product quality and cutting energy costs. After switching to PURE5™ Extraction technology, they reported:

| Metric | Before PURE5™ | After PURE5™ |

|---|---|---|

| Extraction Throughput | 200 kg/day | 600 kg/day |

| Energy Consumption | 450 kWh/day | 150 kWh/day |

| Product Purity & Profile | Good, some terpene loss | Excellent, full spectrum |

| Regulatory Compliance | Complex, high oversight | Simplified, low burden |

Why Natural & Full-Spectrum Extraction is a Game-Changer

Modern cannabis consumers increasingly demand products that deliver the full entourage effect – the synergistic benefits created by cannabinoids, terpenes, and other phytochemicals working together. Industrial methods that sacrifice minor cannabinoids or delicate terpenes fall short.

PURE5™ Extraction’s low-pressure, low-temperature approach preserves all botanical constituents intact without using harmful additives or leaving solvent residues. This means your final extracts are as close as possible to the raw plant’s natural profile – pure, potent, and safer for consumers.

Final Thoughts: Scaling Safely is Key to Future Growth

Successfully scaling industrial cannabis extraction requires a smart balance of technology, safety, product quality, and regulatory compliance. Investing in proven extraction equipment like PURE5™ guarantees not only operational efficiency but also the integrity of your full-spectrum botanical extracts.

By prioritizing safety and sustainability, you reduce risks while increasing yields and profits. Embrace advanced extraction technology today to meet the booming demand for premium cannabis extracts – all while keeping your business future-proof and compliant.

Ready to scale your cannabis extraction operation safely and sustainably? Explore PURE5™ Extraction solutions and discover the difference a natural, foolproof process can make.