Large-Scale Cannabis Extraction: Key Considerations

As the cannabis industry continues its rapid growth worldwide, large-scale cannabis extraction has become a cornerstone process for producing high-quality concentrates, oils, and full-spectrum extracts. Businesses aiming to scale up their operations face unique challenges and opportunities, from ensuring operational efficiency to preserving the natural profile of the botanical compounds. In this comprehensive article, we’ll explore the key considerations for large-scale cannabis extraction and how innovative technology like PURE5™ Extraction plays a pivotal role in delivering superior results.

Understanding Large-Scale Cannabis Extraction

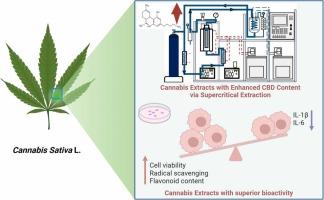

Large-scale cannabis extraction involves processing substantial quantities of cannabis biomass to obtain concentrated extracts rich in cannabinoids, terpenes, flavonoids, sterols, and other valuable compounds. These extracts serve a variety of applications including medicinal products, edibles, tinctures, topicals, and vape products.

Scaling up extraction demands equipment and processes that can handle volume without sacrificing quality. To meet regulatory standards and optimize profitability, operators must carefully consider extraction methods, equipment capabilities, and process control.

Key Considerations for Large-Scale Cannabis Extraction

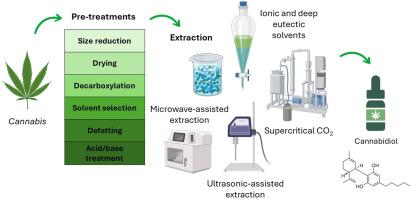

1. Extraction Method & Equipment Choice

Choosing the right extraction equipment is critical. Popular methods include CO2 extraction, hydrocarbon extraction, and ethanol extraction, each with pros and cons. However, technologies like PURE5™ Extraction stand out with their streamlined, automatic, and foolproof process that uses low pressure and low temperature. This technique preserves 100% of all botanical nutrients and delicate compounds such as minor cannabinoids and terpenes, producing a natural, full-spectrum extract.

2. Yield and Recovery Rates

Higher yields mean better profitability. Efficient equipment should maximize cannabinoid and terpene recovery while minimizing waste. PURE5™ technology boasts faster processing speeds paired with higher yields, ensuring optimal extraction efficiency without compromising the botanical profile.

3. Preservation of Botanical Integrity

Maintaining the purity and complexity of cannabis extracts is essential, especially for medicinal applications. Extraction under low temperature and pressure conditions safeguards phytochemicals-including flavonoids, sterols, and minor cannabinoids-ensuring the final product is nutrient-rich and free from solvent residues or additives.

4. Regulatory Compliance and Safety

Compliance with local and international regulations is non-negotiable. PURE5™ Extraction’s low regulatory requirements reduce the complexities associated with permits and environmental controls, making adoption smoother. Furthermore, the closed-loop system recycles solvents entirely, minimizing hazardous waste and environmental impact.

5. Operational Cost Efficiency

Operating large-scale extraction facilities can be resource-intensive. PURE5™ extraction systems use notably low power, reducing electricity consumption and lowering overall operational costs. Coupled with their relatively low initial investment price, this provides a strong return on investment for cannabis processors and botanical extractors alike.

Benefits of Using PURE5™ Extraction for Large-Scale Operations

| Benefit | What It Means for Your Operation |

|---|---|

| 100% Preservation of Botanical Nutrients | Full-spectrum extracts rich in cannabinoids, terpenes, sterols, and flavonoids |

| Low Temperature & Pressure Process | Ensures no degradation or loss of delicate compounds during extraction |

| Fast Processing | Higher throughput to meet large-scale volume demands efficiently |

| Low Power Consumption | Cost savings on energy bills for more profitable operations |

| Low Regulatory Requirements | Simplifies compliance, speeding up time to market with less red tape |

| No Solvent Residue | Cleaner extracts that are safe and natural, appealing more to health-conscious consumers |

Practical Tips for Scaling Your Cannabis Extraction

- Start with a clear process design: Define your extraction goals, batch sizes, and product specifications upfront to select the best equipment.

- Invest in automation: Automation reduces human error, ensures consistency, and speeds up processing time.

- Monitor quality closely: Capture data on cannabinoid profiles, yield percentages, and solvent purity throughout the process.

- Maintain equipment routinely: Prevent downtime with regular maintenance tailored to the sensitivity of extraction components.

- Train your staff: Skilled operators can optimize extraction parameters and troubleshoot issues effectively.

Case Study: PURE5™ in Large-Scale Cannabis Extraction

An industrial cannabis cultivator operating a 10,000-acre farm in the United States integrated PURE5™ Extraction equipment to upgrade their extraction facility. By switching to low-temperature, low-pressure extraction, they achieved:

- A 30% increase in cannabinoid yield compared to previous ethanol extraction methods

- Zero solvent residues detected in the extract, meeting the strictest compliance regulations

- Reduced power usage by 40%, cutting operating expenses substantially

- Enhanced preservation of terpenes and minor cannabinoids leading to a superior product flavor and potency profile

This case exemplifies how strategic equipment choices impact both product quality and operational efficiency at scale.

Conclusion

Large-scale cannabis extraction requires a delicate balance between throughput, quality, and cost-efficiency. Selecting an extraction method and equipment that respects botanical integrity while delivering high yields is paramount. PURE5™ Extraction technology represents a game-changing solution with its automatic, low-pressure, low-temperature process that preserves every nuance of the plant’s full spectrum. Its low power usage, minimal regulatory needs, and solvent recycling capabilities also make it the smart choice for scaling cannabis extraction sustainably and profitably.

Investing in advanced extraction technology today sets your business up for future growth and positions you at the forefront of cannabis innovation.