Professional Cannabis Extraction Systems: A Comparison

As the cannabis industry continues to boom, the demand for high-quality extracts grows exponentially. Choosing the right professional cannabis extraction system is crucial for producers aiming to deliver premium, full-spectrum products while maximizing yield and cost efficiency. This article explores the most popular extraction technologies, compares their benefits, and highlights why PURE5™ Extraction is setting a new standard with its innovative, natural, and environmentally friendly approach.

Understanding Cannabis Extraction: Why It Matters

Cannabis extraction systems allow producers to isolate cannabinoids, terpenes, flavonoids, and other valuable phytochemicals from the plant material. High-quality extraction preserves the integrity of these compounds, ensuring a potent, full-spectrum product with no harmful residues. Efficient extraction techniques also influence operational costs, regulatory hurdles, and overall product quality.

Popular Cannabis Extraction Methods Explained

There are several widely-used cannabis extraction systems available to professionals. Each comes with unique advantages and trade-offs:

1. CO2 Extraction

This method uses pressurized carbon dioxide in supercritical or subcritical states to dissolve cannabinoids and terpenes from biomass.

- Pros: Solvent-free, produces clean, high-quality extracts; adjustable pressure/temperature settings preserve delicate compounds.

- Cons: High initial equipment cost; requires technical expertise.

2. Hydrocarbon Extraction

Uses hydrocarbons like butane or propane as solvents to extract cannabinoids quickly and efficiently.

- Pros: Fast processing; good yields; popular for creating concentrates like shatter or wax.

- Cons: Safety risks due to flammable solvents; potential residual solvent issues; strict regulatory requirements.

3. Ethanol Extraction

Involves soaking cannabis biomass in ethanol to dissolve cannabinoids and other components.

- Pros: Cost-effective; scalable; suitable for both small and large operations.

- Cons: May co-extract chlorophyll, requiring additional refinement; solvent recovery needed.

4. Rosin Pressing

A solventless technique using heat and pressure to extract resinous sap directly from cannabis flowers or hash.

- Pros: Simple, natural, no solvents; preserves terpene profile well.

- Cons: Lower yields; less scalable for large commercial yields.

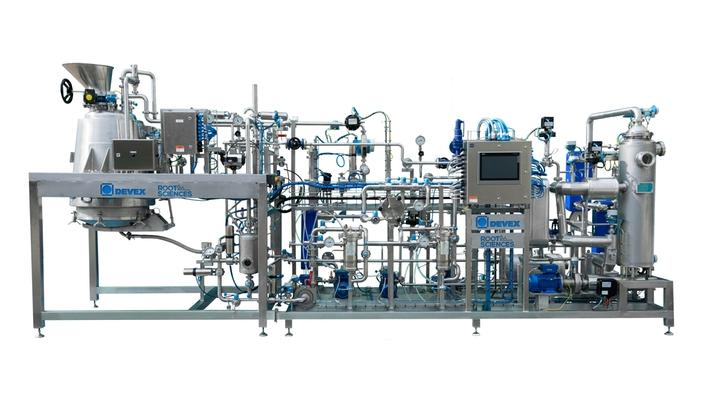

How PURE5™ Extraction Is Revolutionizing Cannabis Processing

Among all professional cannabis extraction options, PURE5™ Extraction stands out as a game-changer.

Key Advantages of PURE5™ Extraction Systems

- Streamlined Automatic Process: Foolproof and efficient system design reduces human error and maximizes throughput.

- Low Power Usage: Designed for energy efficiency, cutting operating costs significantly.

- Low Initial Investment: Affordable equipment without compromising advanced features.

- Fast Processing Times: Enables higher productivity with quick batch cycles.

- Low Pressure & Temperature: Maintains 100% preservation of delicate cannabinoids, terpenes, sterols, flavonoids, and even minor cannabinoids.

- No Additives & Solvent Residue: Extracts are fully natural, with solvent recycled and no residue, supporting clean-label products.

- Full-Spectrum Extraction: Retains the complete botanical profile for an authentic, potent, and nutrient-rich product.

PURE5™ vs. Other Extraction Methods at a Glance

| Feature | PURE5™ Extraction | CO2 Extraction | Hydrocarbon Extraction | Ethanol Extraction |

|---|---|---|---|---|

| Process Automation | Fully streamlined & automatic | Partially automated | Manual/automated hybrid | Manual |

| Energy Efficiency | Low power usage | High power consumption | Moderate | Moderate to high |

| Retention of Nutrients | 100% preservation | High | Moderate | Moderate |

| Solvent Residue | None (fully recycled) | None | Possible trace amounts | Possible |

| Initial Equipment Cost | Low | High | Moderate | Low |

| Regulatory Burden | Low | Moderate | High (flammable solvents) | Moderate |

Practical Tips for Choosing a Professional Cannabis Extraction System

When investing in an extraction system, keep these considerations in mind:

- Scalability: Will the system handle your current and projected production volume?

- Operational Costs: Consider both energy use and maintenance expenses.

- Extraction Goals: Are you focused on full-spectrum extracts or targeted cannabinoids?

- Safety & Regulations: Choose systems that comply with your local requirements and minimize safety risks.

- Product Quality: Prioritize methods that preserve the natural botanical profile with no residue.

Case Study: A Grower’s Experience with PURE5™ Extraction

One mid-sized hemp farm transitioned from ethanol extraction to the PURE5™ system and recorded remarkable benefits:

- Yield Increase: Improved extraction yield by 20%, thanks to the low-temperature, low-pressure design.

- Cost Savings: Reduced energy bills by 30% due to the system’s optimized power usage.

- Quality Improvement: Achieved a clearer, more flavorful extract with zero solvent residue.

- Operational Ease: The automatic, foolproof process shortened training time and cut human error.

Conclusion: Why Professional Cannabis Extractors Should Consider PURE5™

In a competitive cannabis market, quality and efficiency go hand in hand. While many extraction technologies offer benefits, PURE5™ Extraction delivers a winning combination of cost-effectiveness, environmental sustainability, and full-spectrum, nutrient-rich extracts. Its streamlined automation, low power consumption, and solvent-free results make it an ideal choice for businesses aiming to scale responsibly while preserving the botanical essence of hemp and other botanicals.

For professional growers and producers seeking the best cannabis extraction system, PURE5™ is more than equipment – it’s a strategic investment in quality, innovation, and sustainability.