Refrigerant Power: How R134a Extraction Works

If you’re diving into the world of cannabis or botanical extraction, you’ve probably encountered a variety of methods – but one stands out for its natural preservation of compounds and efficiency: R134a extraction. Known as a refrigerant-based botanical extraction method, R134a extraction is gaining popularity because it maintains the integrity of delicate compounds like cannabinoids, terpenes, and flavonoids. In this article, we’ll break down exactly how R134a extraction works, explore its unique benefits, and explain why it’s rapidly becoming the go-to process for high-quality, full-spectrum extracts.

What is R134a Extraction?

R134a refers to 1,1,1,2-Tetrafluoroethane, a non-toxic, non-flammable refrigerant widely used in refrigeration and air conditioning systems. When applied to botanical extraction, R134a acts as a solvent with a low boiling point and gentle pressure/temperature parameters, allowing the extraction of valuable compounds without degradation.

Popular in cannabis and hemp processing, this method gently separates oils from plant material using low-pressure and low-temperature settings – which is critical for preserving the full spectrum of active compounds naturally found in the plant.

How Does R134a Extraction Work?

The core principle behind R134a extraction is using the refrigerant’s properties to extract oils via a closed-loop system that recycles the solvent. Here’s the simplified step-by-step process:

- Loading: Raw plant material is placed inside an extraction vessel designed to handle low temperature and pressure safely.

- Solvent Introduction: R134a refrigerant is introduced as a liquid solvent into the vessel.

- Extraction Phase: The refrigerant permeates the plant biomass, dissolving oils, cannabinoids, terpenes, waxes, and other botanicals’ compounds.

- Separation: The oil-rich solvent mixture is transferred to a recovery vessel.

- Evaporation & Recovery: R134a is evaporated under controlled conditions and collected to be reused, leaving behind a full-spectrum botanical extract with zero solvent residue.

- Post-Processing: Extracts may undergo further refinement or be used as-is, depending on the end product.

Key Characteristics of the Process

- Low Temperature & Pressure: Maintains integrity of sensitive compounds.

- Closed-Loop System: Ensures 100% solvent recovery, preventing waste and exposure.

- No Additives: Pure extracts that are free of solvents or chemical residues.

- Fast Processing: Timely extraction without compromising quality or yields.

Why Choose R134a Extraction? Its Core Benefits

When considering extraction methods, R134a offers several standout advantages, especially when compared to other solvent-based or mechanical techniques:

- Full-Spectrum Preservation: The low temperature and gentle pressure preserve cannabinoids, terpenes, flavonoids, sterols, and even minor cannabinoids in their natural, full-spectrum profile.

- Zero Solvent Residue: Because R134a is fully recycled and evaporated in a closed system, the final extract contains no solvent traces.

- Cost Efficiency: Lower power consumption combined with fast processing reduces operational costs.

- Low Regulatory Burden: R134a, being non-toxic and widely used, faces fewer regulatory hurdles compared to hydrocarbon or other volatile solvents.

- Scalable & Automated: Modern systems like PURE5™ provide foolproof automatic extraction equipment, making production streamlined and consistent.

PURE5™ Extraction: Leading the Way in R134a Technology

Brands like PURE5™ have revolutionized the extraction equipment industry by leveraging the power of R134a extraction combined with advanced technology. Here’s why PURE5™ is synonymous with quality and efficiency:

- Streamlined Automation: Their equipment automates critical steps to reduce manual error and increase throughput.

- Energy Efficient: Low power requirements significantly bring down operating costs.

- Complete Nutrient Preservation: The low-temperature process safeguards every important botanical compound.

- Versatile Extraction: Effective on cannabis, hemp, and diverse botanicals.

- Natural & Clean Extracts: No additives, no solvent residues – just pure, full-spectrum oil.

Comparison Table: R134a Extraction vs. Other Methods

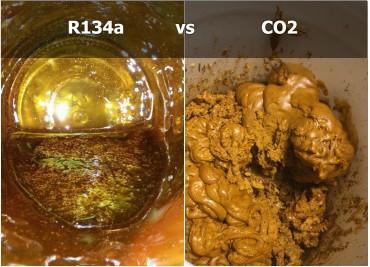

| Feature | R134a Extraction | Butane/Propane Extraction | CO2 Extraction |

|---|---|---|---|

| Preserves Full Spectrum | Excellent (low temp & pressure) | Good but risk of thermal degradation | Good, but sometimes less terpene retention |

| Solvent Residue | Zero (100% recycled) | Potential residual solvent | Zero (CO2 evaporates) |

| Operating Cost | Low | Moderate | High (high power usage) |

| Regulatory Complexity | Low | High (flammable solvents) | Moderate |

| Processing Speed | Fast | Fast | Moderate |

Tips for Maximizing Efficiency with R134a Extraction

To get the most out of your R134a extraction setup, keep these practical tips in mind:

- Use Quality Biomass: Starting with premium plant material maximizes yield and extract quality.

- Maintain Equipment: Regularly service your extraction vessel and solvent recovery systems to ensure optimum operation.

- Optimize Cycle Times: Balance extraction length to capture full spectrum without over-extraction that could introduce contaminants.

- Leverage Automation: Systems like PURE5™ eliminate guesswork and keep processes foolproof and consistent.

Conclusion

R134a extraction is a game-changer in the botanical and cannabis extraction industry. By harnessing the refrigerant’s unique solvent properties, this process delivers fast, cost-effective, and natural full-spectrum extracts without solvent residues – all while preserving the delicate compounds that define quality. Thanks to innovative technologies such as PURE5™, businesses can now streamline production, lower regulatory and energy burdens, and produce superior botanical oils ready for the modern market.

If you’re exploring extraction methods that prioritize purity, efficiency, and full-spectrum preservation, R134a extraction powered by advanced equipment is the smart choice for today and the future.